Take the guesswork out of diagnosis and protect your valuable asset.

Adding locations and more fresh food offerings result in bigger and more complicated refrigeration systems. Save your time and energy. Maintaining your refrigeration systems doesn’t have to be complicated. Introducing, CoreSense Technology. With CoreSense, compressors are equipped with protection modules that keep an eye on critical system parameters —shutting down compressors operating in false conditions, resetting them when conditions have stabilized or generating alerts to request maintenance. CoreSense will help maximize system uptime, avoid missed sales opportunities and keep customers coming back.

With CoreSense Diagnostics, technicians use easy to interpret fault codes to remove the guesswork from troubleshooting so you’re up and running fast. And with advanced communications capabilities, CoreSense modules can link to Site Supervisors and store management systems enabling remote monitoring of system conditions, proactive maintenance scheduling, and precise identification of issues even before technicians are assigned to fix them.

CoreSense Technology — a better way to help you optimize your refrigeration systems, so you can stay focused on the things that really matter.

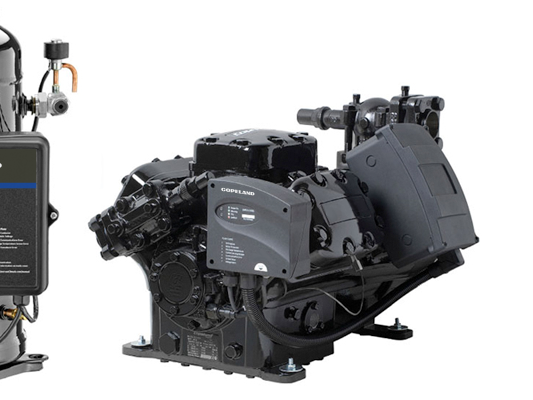

CoreSense™ Protection for Copeland™ Discus Compressors

CoreSense™ Protection technology for Copeland Discus™ compressors is a system of algorithms read off an electronic module, installed on the compressor, that offers a combination of oil and motor protection as well as optional protection against high discharge temperatures and communication compatibility with MODBUS communication devices. Display LEDs show the operational status of the compressor and whether there are any active compressor warnings, trips, or lockouts.

CoreSense™ Diagnostics for Copeland™ scroll compressors

CoreSense Diagnostics for Copeland scroll compressors is a breakthrough innovation to assist contractors in troubleshooting commercial refrigeration system problems. By using the compressor as a sensor, CoreSense Diagnostics gives technicians insight into the system through the compressor, providing valuable information to help diagnose problems quickly and accurately, reducing costly callbacks. CoreSense Diagnostics are now being applied to smaller compressors with the same functionality as the CoreSense module on a Copeland scroll K5 compressor. The Panel Mounted CoreSense Module allows the customer flexibility to retrofit existing applications and fit new designs.

CoreSense Diagnostics for Copeland Discus Compressors

CoreSense™ Diagnostics, available on Copeland™ 2D, 3D, 4D and 6D compressors, integrates a number of important sensing and compressor protection functions. This product provides for on/off control of the compressor, capacity modulation (both conventional blocked suction and with Copeland Discus Digital capacity modulation), and for communication of the compressor status through a network using MODBUS for Intelligent Store communication protocol. Protection against low oil pressure, excessive discharge temperature, high discharge pressure, and low suction pressure is standard on every Copeland Discus compressor with CoreSense Diagnostics. The module features a 2-line liquid crystal display on the front of the compressor that indicates the operational status of the compressor with a choice of 5 languages. An LED on the compressor control module immediately indicates whether or not there is any compressor faults.

Copeland™ Performance Alert

The Copeland™ PerformanceAlert diagnostic module assists in troubleshooting refrigeration system faults. The module can be installed in the electrical box of the condensing unit near the compressor contactor or in the electrical panel of a refrigeration rack system. By monitoring and analyzing data from Copeland™ compressors, the module can accurately detect the cause of electrical and system related issues. A flashing LED indicator communicates the Alert code and guides the service technician more quickly and accurately to the root cause of the problem. The module has alert codes programmed for a three phase reciprocating compressor, three phase scroll compressor, and single phase compressor.