With a legacy spanning over 155 years, Vilter by Copeland stands as a foremost technology and engineering innovator in industrial compression systems, spearheading the energy transition towards highly sustainable solutions for biogas, refrigeration, and heating. Our steadfast dedication to technical innovation and leadership has positioned us as the preferred partner for district and process heating applications, offering modular, scalable, and robust solutions.

Discover the Vilter VQ95 Industrial Heat Pump

Accelerate the energy transition and decarbonize heating with a simple, more reliable system.

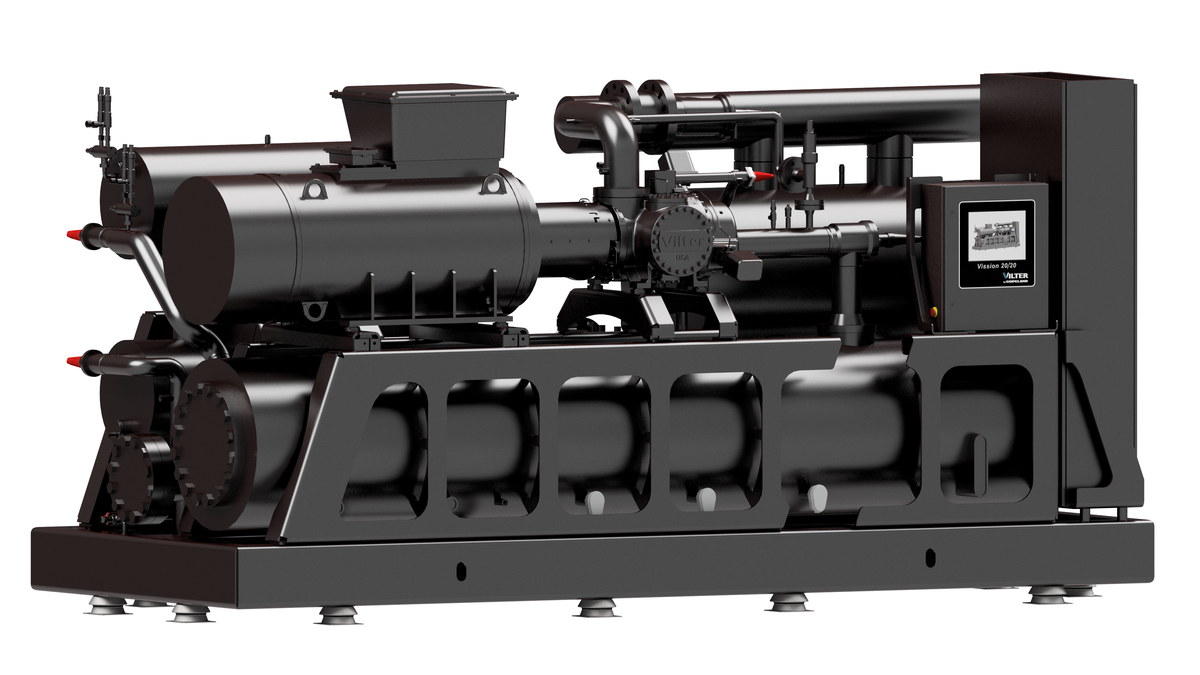

The VQ95 from Vilter by Copeland is a new industrial-grade, single-stage heat pump, designed to decarbonize heating. Engineered in Denmark to meet global energy transition initiatives, the system leverages Vilter single screw technology to enable unprecedented simplicity, reliability, and flexibility. The VQ95 balances these characteristics with a compact footprint, while maximizing efficiency (COP) and minimizing total cost of ownership (TCO).

Industrial Heat Pumps | Vilter by Copeland

Industrial heat pumps offer significant potential for reducing carbon emissions in various operations worldwide. Leading food and beverage processors have embraced these heat pumps, halving energy usage and saving millions of gallons of water annually. Unlike many other promising sustainability solutions, heat pumps are a proven, mature technology commercially available today.

Global Net Zero Emissions Made Possible with Industrial Heat Pumps

Industrial heat pumps combine measurable sustainability benefits with a strong business case in many global regions. The efficiency advantages of heat pumps for heating and cooling offer a significant opportunity to improve sustainability in facilities and support the global green energy transition.

Industrial systems discard a significant quantity of heat to the atmosphere, where heat pumps capture this wasted heat efficiently and use it to cut the fossil fuels burned to heat water. Industrial heat pumps are environmentally friendly and economical, allowing operators to make the most of their energy resources.

- Decrease reliance on fossil fuels in operational processes and reduce GHG emissions

- Achieve 3-5 times higher efficiency compared to conventional fossil fuel-based heating systems

- Harness renewable energy sources such as solar or wind power

- Enable simultaneous heating and cooling capabilities

- Utilize surplus heat generated by existing industrial processes

- Ensure regulatory adherence and alignment with ESG standards

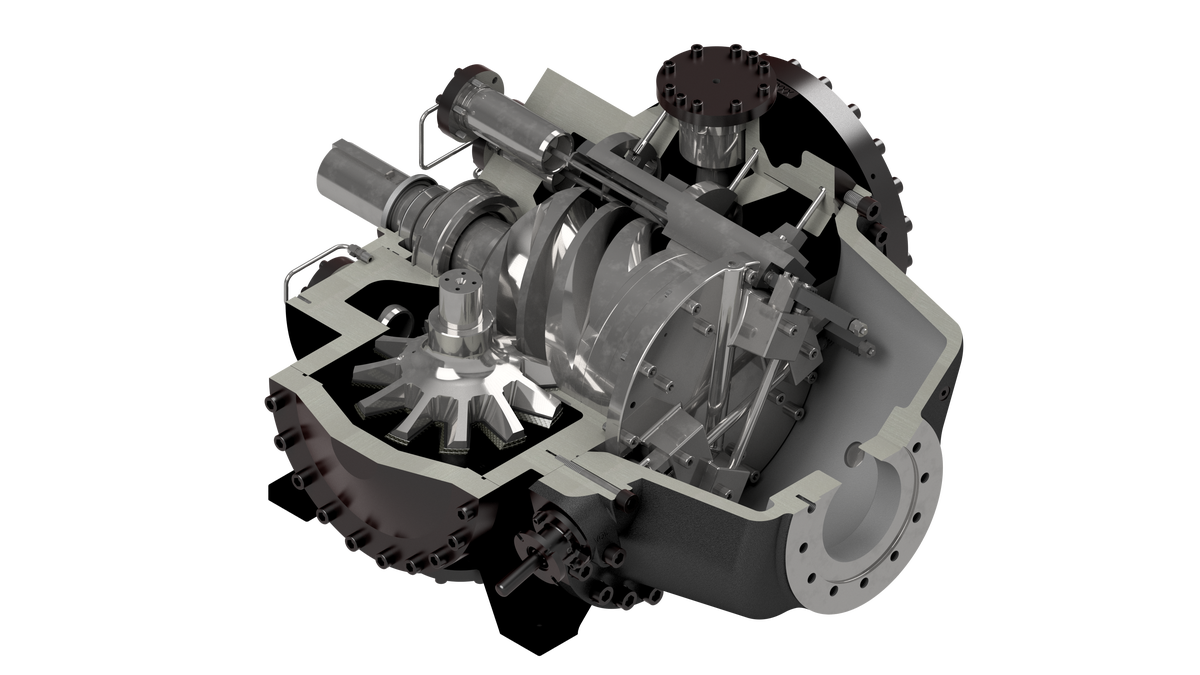

Industry Leading Single Screw Technology

Our transformational solutions are powered by the efficient Vilter single screw compressor, which enables industry leading up-time over decades of operation.

- Balance of axial and radial loading extends bearing lifespan for improved durability

- Precision mechanical modulation of capacity and pressure ratio through Parallex Slides enhances operational flexibility

- Tolerance to liquid droplets eliminates the need for superheat, boosting COP

- Simplified servicing ensures hassle-free maintenance

- Proven resilience in the most challenging environments, ensuring reliable performance

- Extensive 15-year track record of operating in heat pump duty at temperatures of up to 90°C, demonstrating robustness and longevity

Inside Story

See what makes the Vilter by Copeland single-screw compressor so unique.

To achieve the global decarbonization of industry by 2050, the development and implementation of scalable heat pump solutions is essential.

Standard x Flexible = Scalable

This equation represents a new approach to expedite the energy transition to a sustainable future. With a focus towards a scalable, modular package, Vilter is helping push the adoption of industrial heat pump technology - while making decarbonization a key priority for industrial applications.

- Remove the complexity of quoting, installing, and servicing

- Ensure the longevity of your operations, while minimizing service intervals

- Configure to your application needs and maximize COP

Purpose-built and expertly-crafted to decarbonize heating, the Vilter heat pump solutions are backed by the foundational elements of performance, reliability, and simplicity.

Think big: Simple heat pump solutions above 1 megawatt

Copeland research and development is proving the advantages of medium to large scale industrial heat pumps. Current food and beverage processing and district heating applications illustrate how the demand for electrification of space and water heating accelerates with industrial grade heat pumps from 1 – 5 MW using ultra-low GWP natural refrigerants.

Learn more in this comprehensive primer, highlighting the key considerations and strategies for applying heat pumps in commercial and industrial markets.

Industrial Heat Pumps Deliver Sustainability, Lifecycle Benefits in Food and Beverage Industry

The food and beverage industry faces increasing pressure to reduce scope 1, 2 and 3 emissions. In addition to the need to comply with national and regional regulations, many organizations have set internal sustainability targets as part of their environmental, social and governance (ESG) goals.

Leading food processors are using heat pumps to cut energy costs by as much as 50 percent. Explore how heat pumps are unlike many other promising sustainability solutions as a proven, mature technology that’s commercially available today.

Global Innovation: CO₂ Industrial Heat Pump Solution

An innovative heat pump pioneered by Copeland and Hydro Quebec passed 15,000 hours of testing, further validating the ability to use CO2 (R744) for the simultaneous heating and cooling of large buildings. This eco-friendly heat pump solution reduces greenhouse gas emissions and improves energy efficiency while offering load flexibility to building operators