Results:

- Saves millions of liters of water annually and cuts the cost of cooling it

- Significant energy savings

- Complete system connectivity for remote monitoring and diagnosis

- Greatly reduced maintenance costs

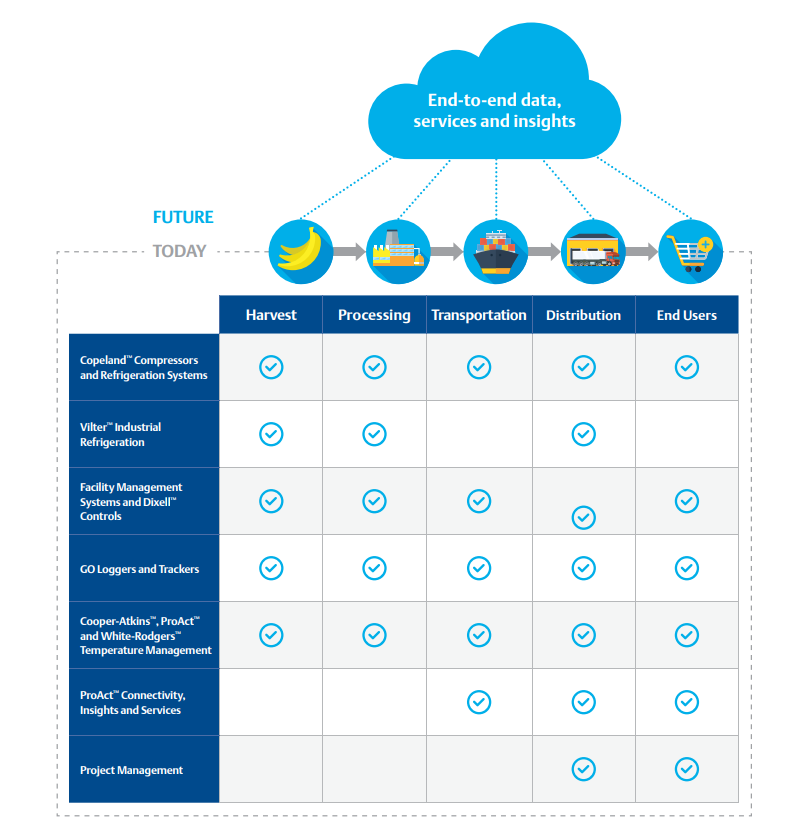

Copeland has solutions for critical areas, applications and markets