Refrigerant leak detection is considered a fundamental component and compliance necessity in commercial refrigeration system design. Regardless of refrigerant type, reducing leaks is important for a variety of performance, environmental and safety reasons. The Copeland C-Series Refrigerant Leak Detection System (CRLDS) monitors indoor air for any refrigerant leaks and can detect a wide range of gases. The CRLDS can be used standalone or with the Site Supervisor or E2/E3 controllers. You can use the CRLDS to continuously monitor for refrigerant leaks or as part of compliance monitoring or a refrigerant management program.

Benefits

| Message Topic | Key Message | Proof Points |

|---|---|---|

| ENVIRONMENT | Helps customers meet ESG goals. | Detects leaks of harmful GHGs, alerts that maintenance is needed to prevent further release of pollutant gases. |

| SAFETY | Helps customers to keep their employees and customers safe from harm. | Detects toxic refrigerants that create a risk of asphyxiation (either directly or via oxygen displacement) and alerts that action must be taken. |

| SIMPLICITY | Broad-band sensor types detect most refrigerants with limited part numbers. Easy to install, configure, and maintain, providing both analog and digital interfaces. | Only 3 different sensor variants needed to cover all common refrigerants. Bluetooth app and analog service wheel, simple calibration, pre-calibrated sensor exchange. |

| INTEGRATION | Integrates seamlessly into Supervisory system. | Multiple standardized output options, including MODBUS, relays for alarm & fault, analog output (ie. 4-20mA, 0-10V). Native integration into Copeland Supervisory system in progress. |

| RELIABILITY | Reliability saves customers time in dealing with product failures & false alarms, allowing them to focus on maximizing the efficiency of the refrigeration system. | Less than 0.001% product failure rate. |

| INSTALLATION | Off-the-shelf refrigerant gas detector that is ready to install. Designed for easy installation & connection of all cables. Designed for use in all typical refrigeration applications. | Pre-configured with alarm levels in compliance with industry standards, and fail-safe configuration of relays. Number & positioning of cable glands for easy access, pluggable screw terminals can be removed from the board to make connecting cables easy IP67-rated enclosure & -40°C - + 50°C operating range suitable for all typical refrigeration environments. |

| STANDARDS & REGULATIONS | Helps customers to meet required safety standards. | Compliant to: UL61010-1/CSA C22.2 No. 61010-1, EN 61010-1, EN 378, EN 14624, EN 50270, EN 50271, IEC 60529, IEC 60355-2-40, (EMC) 2014/30/EU, (LVD) 2014/35/EU. |

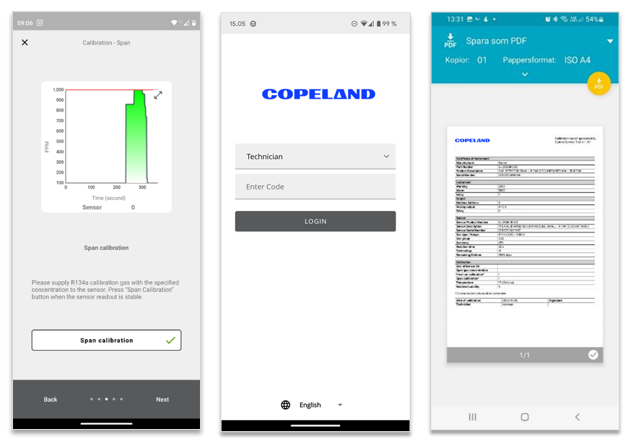

Configure settings via Bluetooth® app for iOS and Android™

- Target gas (HFC/HFO versions)

- Alarm levels

- Alarm behavior (latching, auto-reset)

- Modbus settings

- Analog output settings

- Test mode

- Perform calibration & generate certificate

Manual service wheel via magnetic switch

- Full configuration in settings where Bluetooth® cannot be used